The vinyl record production process is a fascinating blend of art and science. It involves several meticulous steps to transform audio recordings into physical records. Starting with the recording and mastering of the audio, the process proceeds through lacquer cutting, creation of the metal stamper, and pressing the vinyl. Each step requires precision and expertise to ensure the highest quality records. Understanding how vinyl records are made helps us appreciate the craftsmanship involved in producing these beloved music formats.

Recording and Mastering for Vinyl

The Recording Process

Recording music for vinyl begins with capturing high-quality audio in a studio setting. The goal is to create a clean, detailed recording that captures the nuances of the performance. This initial recording phase is crucial as it sets the foundation for the entire vinyl record production process. Here’s a breakdown of the steps involved:

- Setting Up the Studio: Musicians perform their pieces in a controlled studio environment equipped with various microphones and recording equipment.

- Capturing the Performance: The performance is recorded using high-quality microphones placed strategically to capture the best sound. Multiple takes might be recorded to ensure the best version is captured.

- Mixing the Tracks: After recording, the individual tracks are mixed to create a cohesive audio experience. This involves balancing the levels of different instruments and vocals, adding effects, and ensuring the overall sound is polished.

- Creating the Master Recording: The final mix is then prepared as the master recording, which will be used in the mastering process. This master recording should be free of any errors and capture the full dynamic range and clarity of the performance.

High-quality recordings are essential for producing vinyl records that sound great and last a long time. This meticulous attention to detail ensures that the initial audio quality is preserved throughout the subsequent production stages.

Mastering Audio for Vinyl

Mastering vinyl records is a critical step in the production process, preparing the recorded audio for vinyl transfer. Mastering ensures that the music will sound its best when played on a turntable. The mastering process involves several key steps:

- Equalizing the Audio: Adjusting the frequency balance to ensure a clear and well-rounded sound. This step addresses any imbalances that might have occurred during recording and mixing.

- Adjusting Volume Levels: Ensuring that the audio levels are consistent throughout the record. This step prevents any sections from being too loud or too quiet, providing a smooth listening experience.

- Dynamic Range Compression: Applying compression to manage the dynamic range, ensuring that the quiet parts are audible and the loud parts are not overwhelming.

- Sequencing the Tracks: Arranging the tracks in the desired order and ensuring smooth transitions between them.

- Creating the Master Lacquer: The final mastered audio is used to cut the lacquer disc, which will be the template for pressing the vinyl records.

The various factors, including mastering, source material, pressing techniques, and physical properties like vinyl weight and speed, can influence the sound quality of the finished record. Proper mastering is crucial for achieving the optimal sound quality on vinyl. Mastering engineers use specialized equipment and techniques to make the audio suitable for the vinyl format, ensuring clarity, balance, and fidelity.

Unique Characteristics of Vinyl Format

The vinyl record production process must account for the unique characteristics of vinyl as a format. Vinyl records have continuous grooves that store the audio information, offering a distinctive analog sound. Here are some key points about vinyl’s unique characteristics:

- Analog Sound: Vinyl records provide a warm, rich sound that many listeners prefer over digital formats. This is due to the continuous nature of the grooves, which capture a wide range of frequencies and dynamics.

- Frequency Range: Vinyl can capture both very low and very high frequencies, but mastering engineers must manage these carefully to avoid distortion. For instance, very low frequencies might need to be centered to prevent excessive groove movement.

- Physical Limitations: The width and spacing of the grooves on a vinyl record must be carefully controlled. Too wide, and the record won’t fit enough music; too narrow, and the sound quality may suffer.

- Playback Variability: The sound quality can vary depending on the turntable and needle used, which means the mastering process must ensure the record sounds good across various playback systems.

Challenges in Vinyl Mastering

Mastering vinyl records presents several challenges that engineers must navigate to produce high-quality records. These include:

- Groove Width and Spacing: Engineers must carefully manage the width and spacing of the grooves to ensure optimal playback quality and to fit the desired amount of music on each side of the record.

- Frequency Management: Certain frequencies, particularly very low and very high ones, must be managed carefully to prevent distortion and to ensure they translate well to the vinyl format.

- Analog Imperfections: The analog nature of vinyl means that any imperfections in the audio can be more noticeable. Engineers need to minimize these imperfections while maintaining the integrity of the original recording.

- Balancing Dynamics: Engineers must strike a balance between maintaining the dynamic range of the recording and ensuring it sounds good on vinyl. Over-compression can lead to a flat sound, while under-compression can result in playback issues.

Mastering vinyl requires a deep understanding of both the technical and artistic aspects of the format. By carefully navigating these challenges, mastering engineers ensure that the final product delivers the best possible listening experience on vinyl.

Lacquer Cutting Process

Introduction to Lacquer Cutting

The lacquer-cutting process is a crucial step in the vinyl record production process. It involves transferring the mastered audio onto a lacquer disc, which serves as the master copy for pressing records. The precision required in this step is immense, as any errors in the cutting process can result in defects in the final vinyl records. Understanding this step is essential to appreciating the overall craftsmanship involved in vinyl production. Lacquer cutting for vinyl requires specialized equipment, including a precision cutting lathe. This machine engraves the audio signal onto the lacquer disc by creating grooves that correspond to the sound waves. The cutting lathe must operate with extreme accuracy to ensure the grooves are correctly formed. This precision is vital to ensure the final vinyl records play back the audio without distortion or other issues.

Transferring Audio to Lacquer Disc

The process of transferring audio to a lacquer disc involves carefully guiding the cutting stylus to engrave the grooves onto the disc. The stylus must move smoothly and consistently, maintaining the correct depth and width of the grooves. This step is where the audio signal is physically etched into the lacquer, making it a permanent representation of the mastered audio. The quality of this transfer is critical for the overall sound quality of the final vinyl records.

Skill and Expertise Required for Lacquer Cutting

Lacquer cutting for vinyl is a highly skilled task that requires extensive knowledge and experience. Engineers who cut lacquers must understand the intricacies of audio signals and the mechanical aspects of the cutting lathe. Their expertise ensures that the audio is accurately represented on the lacquer disc, laying the foundation for high-quality vinyl records. The skill involved in this process highlights the artisanal nature of vinyl record production.

The Technical Process of Cutting and Preparing the Master Disk

Cutting the master disk is a highly specialized and technical step in vinyl record production, serving as the foundation for all subsequent copies. This process begins with a precision cutting lathe, where a skilled engineer transfers the mastered audio onto a lacquer-coated aluminum disc. The lathe’s cutting stylus, often made of sapphire, engraves a continuous spiral groove that precisely mirrors the audio signal. Throughout this step, environmental conditions, such as dust and temperature, are tightly controlled to prevent imperfections. Once the lacquer master is cut, it undergoes a meticulous inspection for flaws or inconsistencies. The master is then carefully cleaned and coated with a thin layer of metal, typically silver or nickel, to prepare it for electroplating. This preparation ensures that the delicate grooves are faithfully captured in the subsequent metalwork stages, laying the groundwork for producing durable stampers used in mass replication of vinyl records.

Creating Metal Stampers

Electroplating Stages

Creating metal stampers is a key part of the vinyl record manufacturing process. It begins with electroplating, where the lacquer master is coated with metal to create a negative impression. This negative is then used to form a positive metal stamper. The electroplating process involves several stages, including applying a thin layer of silver or nickel to the lacquer and then building up additional layers to strengthen the stamper.

Producing Durable Metal Molds

The goal of the electroplating process is to produce durable metal molds, or stampers, that can withstand the pressure of vinyl pressing. These stampers are essential for mass-producing vinyl records, as they imprint the audio grooves onto the vinyl pellets during the pressing stage. The durability of these stampers ensures that they can be used to press multiple copies of the record without degrading, maintaining consistent quality across all copies.

Steps in Making Metal Stampers

The process of making metal stampers involves several meticulous steps. First, the lacquer master is coated with a thin layer of metal to create a metal master. This metal master is then used to produce a metal mother, which is a positive copy. The metal mother is used to create the final stampers, which are negative copies used for pressing vinyl records. Each step must be carefully executed to ensure accuracy and quality. Accuracy in creating metal stampers is critical for maintaining high-quality sound in the final vinyl records. Any imperfections in the stampers can result in defects in the pressed records, affecting playback quality. Quality control measures are in place throughout the electroplating and stamping creation process to ensure that the final stampers are precise and free of defects. This attention to detail is crucial for producing high-fidelity vinyl records.

Vinyl Pressing Techniques

Learn the actual pressing of vinyl records, including the materials used, the pressing machinery, and the formation of the physical records.

Heating and Pressing Vinyl Pellets

The process of vinyl pressing techniques begins with heating vinyl pellets until they become soft and pliable. Here’s a breakdown of the steps involved:

- Heating the Pellets: Vinyl pellets are placed into a hopper where they are heated to a specific temperature, making them soft and malleable.

- Positioning the Pellets: The heated vinyl is then placed between two metal stampers inside the pressing machine. These stampers have a negative image of the grooves that need to be imprinted on the vinyl.

- Applying Pressure: The pressing machine closes, applying significant pressure to the vinyl pellets. This pressure forces the vinyl to conform to the shape of the stampers, imprinting the grooves accurately.

- Forming the Record: As the vinyl is pressed, it takes the form of a flat disc with grooves that replicate the original audio. This step is critical for ensuring high-quality sound reproduction.

Precision in this process is essential to ensure that the audio grooves are accurately replicated, resulting in high-quality sound reproduction. The accurate transfer of the grooves ensures that the record will produce clear and precise audio when played.

Types of Vinyl Pressing Machines

There are several types of machines used in vinyl record manufacturing, each with its advantages:

- Manual Presses: These presses require an operator to handle each step of the pressing process. While labor-intensive, they allow for more control and are ideal for smaller batches or custom pressings.

- Semi-Automatic Presses: These machines automate some parts of the process while still requiring manual intervention. They strike a balance between efficiency and control, making them suitable for mid-sized production runs.

- Fully Automatic Presses: These presses automate the entire pressing process, from heating the pellets to trimming the finished records. They are ideal for large-scale production due to their efficiency and consistency.

Each type of machine has its advantages, with automatic presses being ideal for large-scale production and manual presses allowing for more hands-on control in smaller batches.

Forming the Final Vinyl Record

The formation of the final vinyl record involves several critical steps beyond just pressing:

- Trimming Excess Vinyl: Once the vinyl has been pressed and the grooves imprinted, the records are trimmed to remove any excess vinyl around the edges. This step ensures that the records have a clean, smooth edge.

- Cooling the Records: After trimming, the records are allowed to cool. This cooling process stabilizes the vinyl, preventing warping and ensuring that the grooves maintain their shape.

- Inspecting for Defects: Each record is inspected for defects such as warping, scratches, or surface imperfections. This inspection is vital to ensure that each record meets the necessary quality standards.

- Packaging and Distribution: Once the records pass inspection, they are packaged and prepared for distribution. Proper packaging protects the records during shipping and ensures they reach consumers in pristine condition.

The attention to detail in this process ensures that each vinyl record delivers the best possible sound and meets high-quality standards before being sold to consumers.

Variations in Pressing Techniques

Vinyl pressing techniques can vary depending on the desired outcome, with several factors influencing the final product:

- Pressing Speeds: Some records are pressed at different speeds, such as 33 1/3 RPM or 45 RPM. The speed can affect the audio characteristics, with 45 RPM often providing better sound quality due to wider grooves.

- Vinyl Thickness: Records can be pressed in various thicknesses, with heavier vinyl (often referred to as 180-gram vinyl) being preferred by audiophiles for its perceived better sound quality and durability.

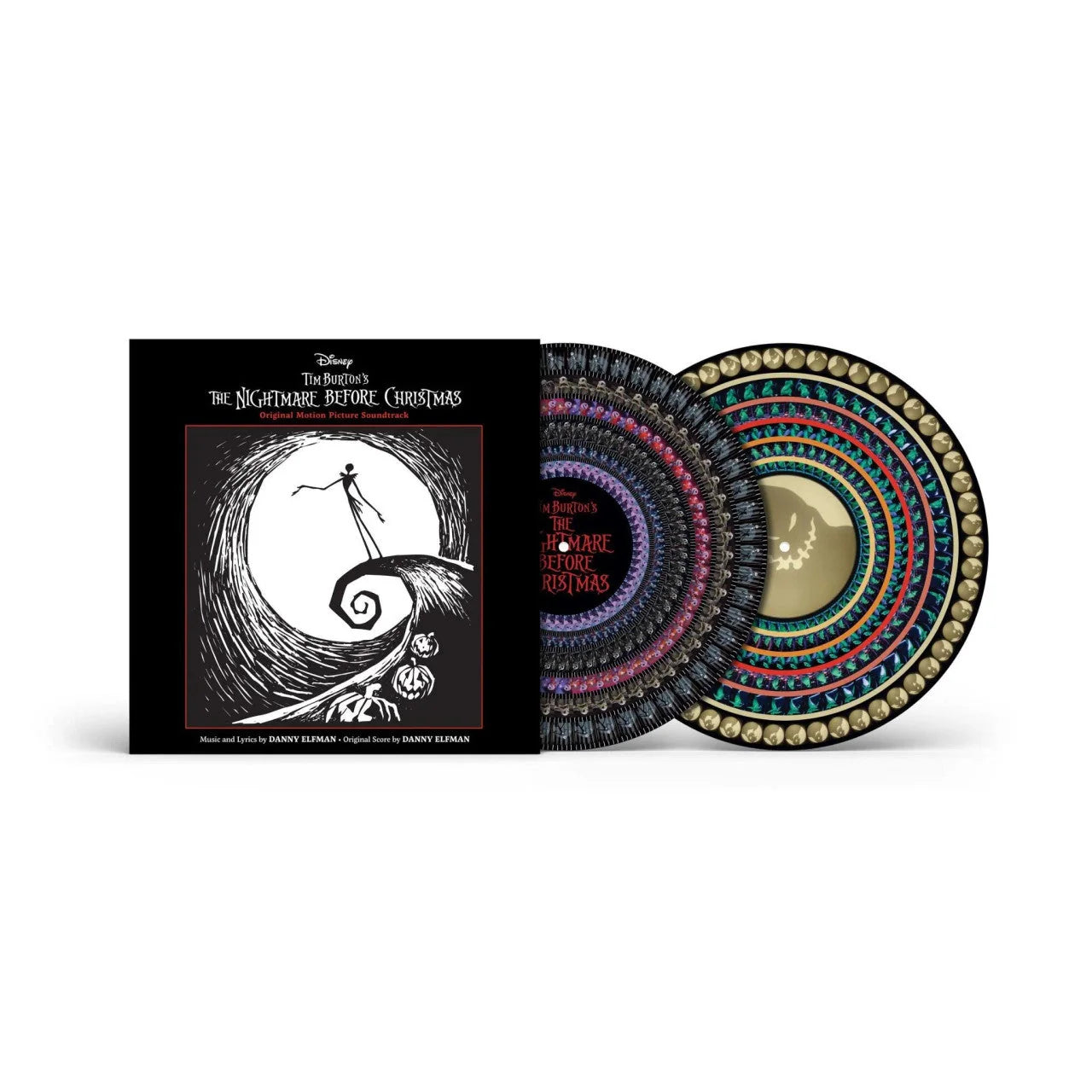

- Color Variations: Vinyl records are traditionally black, but they can also be pressed in various colors or even with unique patterns. Colored vinyl is popular among collectors for its aesthetic appeal.

The unique aspects include colored vinyl, varying vinyl weights, special effects, and considerations for optimal record length and format are important. These variations add to the diversity and appeal of vinyl records, catering to different preferences and tastes. Collectors often seek out these unique records for their special properties, making vinyl a versatile and highly collectible format.

Advanced Vinyl Production Machinery

Presses and Trimming Equipment

Vinyl production machinery includes presses and trimming equipment that are vital for producing high-quality records. Presses apply pressure to the vinyl pellets to form the records, while trimming equipment ensures that the edges of the records are smooth and uniform. This machinery must operate with precision and reliability to maintain consistency in the production process, ensuring that each record meets high standards.

Role of Machinery in Consistency

The role of vinyl production machinery in maintaining consistency cannot be overstated. High-quality machinery ensures that each record produced is identical to the master copy, with no variations in the audio grooves. This consistency is essential for ensuring that listeners experience the music as the artist intended. Reliable machinery also helps minimize defects and improve the overall efficiency of the production process.

Ensuring Quality Throughout Production

Ensuring quality throughout the vinyl record manufacturing process involves multiple checks and balances. From the initial recording and mastering to the final pressing and trimming, each stage includes quality control measures to detect and correct any issues. Advanced machinery plays a crucial role in this process, providing the precision and reliability needed to produce high-quality records consistently.

Innovations in Vinyl Production Technology

Innovations in vinyl production machinery have significantly improved the efficiency and quality of vinyl record manufacturing. Modern presses and cutting lathes use advanced technology to ensure precision and consistency. These innovations include digital controls that allow for more accurate pressing and cutting, reducing the likelihood of defects. Additionally, improved materials and engineering techniques have enhanced the durability and performance of the machinery, further contributing to the high quality of contemporary vinyl records.

Quality Control in Vinyl Manufacturing

The quality assurance steps, such as test pressings, inspections, and reviews, ensure the final records meet desired audio and physical standards.

Visual and Audio Inspections

Vinyl record quality control involves both visual and audio inspections to ensure each record meets high standards. Visual inspections check for physical defects such as warping, scratches, or improper trimming. Audio inspections involve playing the records to check for sound quality issues, such as pops, clicks, or skips. These inspections are crucial for maintaining the high standards expected by vinyl enthusiasts and ensuring a superior listening experience.

Detecting Defects and Imperfections

Quality control technicians use specialized equipment to identify any issues that could affect playback. This includes examining the grooves under magnification and listening for any audio anomalies. Ensuring that any defects are detected and addressed before the records reach consumers is essential for maintaining the integrity of the vinyl record manufacturing process.

Maintaining High Audio Fidelity

Maintaining high audio fidelity is one of the most important aspects of vinyl record quality control. This involves ensuring that the audio is reproduced as faithfully as possible from the master recording. High fidelity means that the sound quality is clear, detailed, and free from distortion. Achieving this requires precise control over every stage of production, from mastering to pressing, and rigorous quality control checks. Quality control standards and practices in vinyl production are designed to ensure that each record meets specific criteria for sound and physical quality. These standards include guidelines for acceptable levels of surface noise, groove integrity, and physical defects. Adhering to these standards helps ensure that consumers receive high-quality records. Continuous monitoring and improvement of these practices are vital for maintaining the reputation of vinyl as a premium music format.

The Analog Sound in Vinyl Records

Understanding Analog Sound

Analog sound in vinyl records refers to the continuous audio signal stored in the grooves of a vinyl record. Unlike digital sound, which is made up of discrete samples, analog sound captures the entire audio wave, providing a more natural and warm listening experience. This characteristic of vinyl is one of the main reasons why many audiophiles prefer vinyl records over digital formats.

Continuous Grooves and Sound Waves

The grooves on a vinyl record are continuous and represent the sound waves of the recorded audio. As the needle of a turntable travels along these grooves, it vibrates to reproduce the sound waves, which are then amplified and heard through speakers. This continuous nature of the grooves allows vinyl records to capture subtle nuances in the music, contributing to the rich and immersive sound that vinyl enthusiasts appreciate.

Warmth and Richness of Vinyl Sound

The warmth and richness of analog sound in vinyl records are often cited as reasons for their enduring appeal. The analog format tends to have a fuller, more rounded sound compared to digital formats. This warmth is partly due to the natural compression that occurs during the vinyl pressing process, which can enhance the mid-range frequencies and provide a more pleasing listening experience. The unique sound characteristics of vinyl make it a preferred format for many music lovers.

Audiophiles’ Appreciation for Analog

Audiophiles’ appreciation for analog sound in vinyl records is rooted in the format's ability to deliver a listening experience that is both detailed and emotive. Vinyl records are often described as having a more "live" sound, making listeners feel closer to the original performance. This connection to the music, combined with the physical and tactile experience of handling vinyl, makes it a beloved format among audiophiles and collectors.

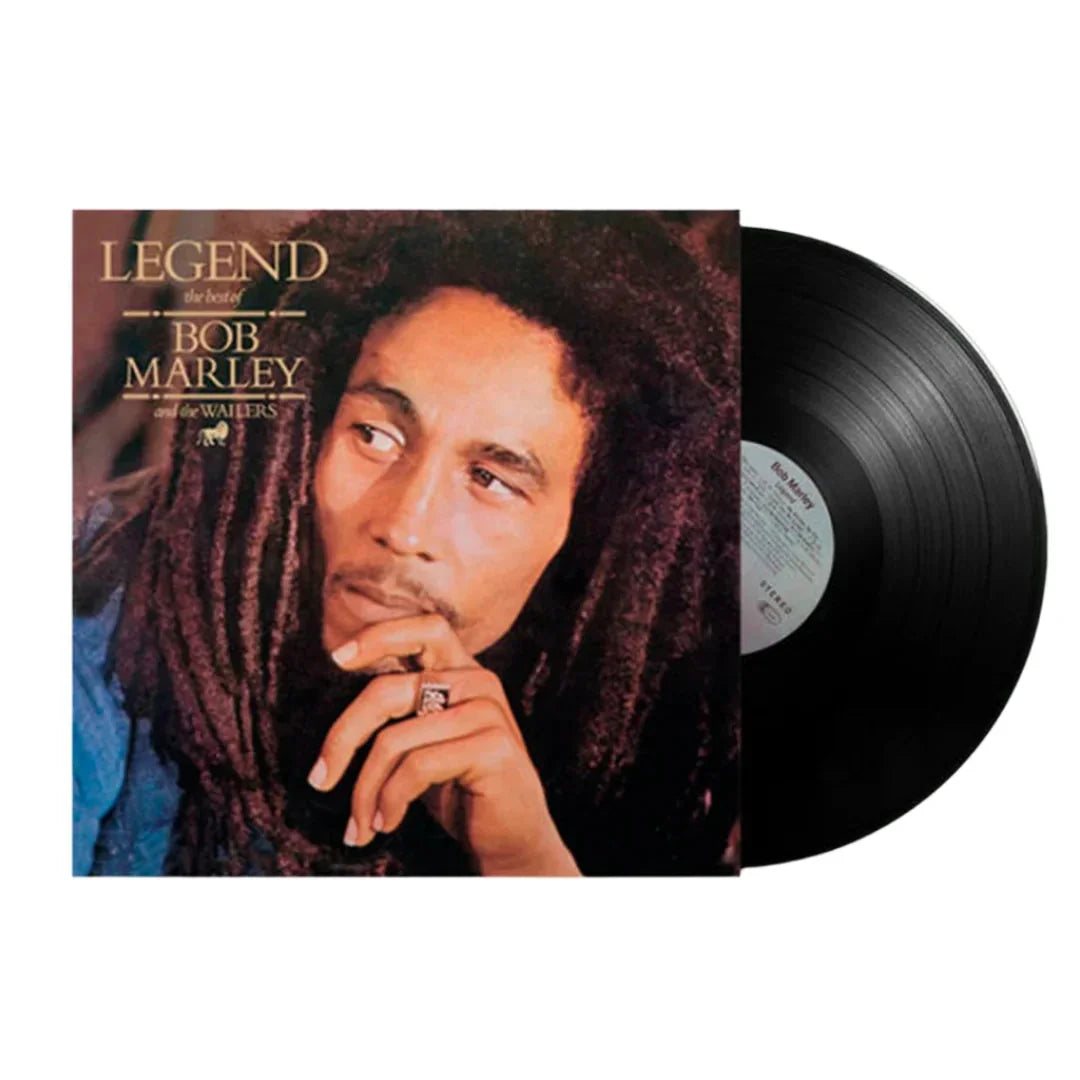

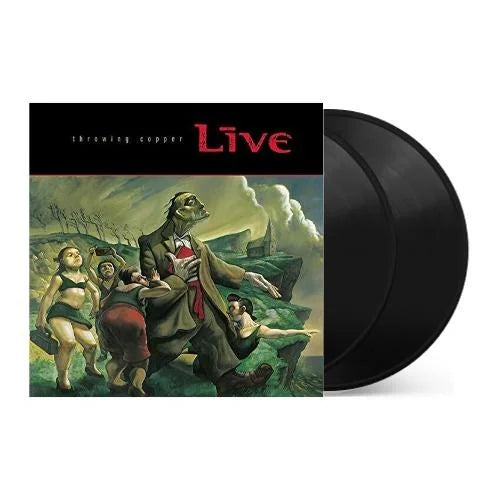

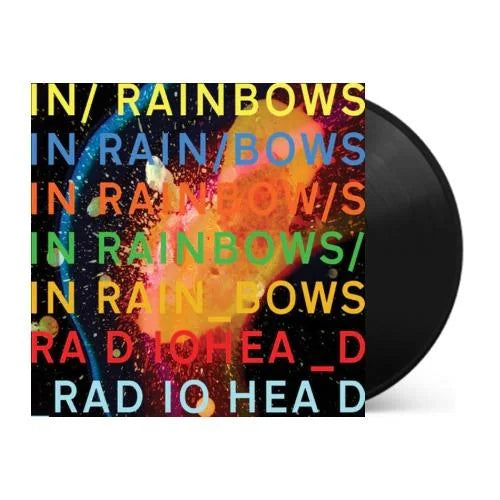

Buying Vinyl Records Online

Benefits of Online Record Stores

Buying vinyl records online offers several benefits. Online record stores provide a vast selection of records, often including rare and hard-to-find items that might not be available in physical stores. Shopping online allows customers to easily compare prices and read reviews, making it easier to find the best deals. Additionally, the convenience of shopping from home and having records delivered directly to your door makes online shopping a popular option for vinyl enthusiasts.

Finding Reputable Online Sellers

Finding reputable sellers is crucial when you buy records online. Look for online record stores with good reviews and a solid reputation. Reputable sellers will provide detailed descriptions and photos of the records, including information about their condition. It's also helpful to check if the seller has a return policy in case the record does not meet your expectations. Conducting some research can help ensure a positive experience when purchasing vinyl online.

Ensuring Authenticity and Quality

Ensuring the authenticity and quality of vinyl records is important when purchasing online. Make sure that the seller provides clear images and descriptions of the record’s condition. If possible, buy from sellers who specialize in vinyl records, as they are more likely to have the knowledge and expertise needed to verify the authenticity of the records they sell. Checking for reviews and ratings can also help ensure you are buying high-quality, genuine vinyl records.

The Role of Online Marketplaces in Vinyl Resurgence

Accessibility of Vinyl Records Online

The accessibility of vinyl records online has played a significant role in the vinyl resurgence. Online marketplaces have made it easier for people to find and purchase vinyl records from around the world. This increased accessibility has introduced new audiences to the format and rekindled interest among those who may have stopped collecting. The convenience of online shopping has been a key factor in the growing popularity of vinyl records.

Diverse Catalog of New and Vintage Records

Online marketplaces offer a diverse catalog of both new and vintage records. This variety allows collectors to find not only the latest releases but also classic albums that are no longer available in physical stores. The ability to access such a wide range of records online has fueled the enthusiasm for vinyl collecting and provided opportunities for new collectors to start their journey with ease. The internet has facilitated the enthusiasm for vinyl by connecting collectors and enthusiasts from all over the world. Online forums, social media groups, and dedicated websites allow vinyl lovers to share their collections, discuss rare finds, and offer advice. This online community has helped to sustain and grow the interest in vinyl, making it more than just a hobby but a vibrant culture that spans the globe.

Impact of Online Marketplaces on Vinyl Popularity

The impact of online marketplaces on vinyl popularity is significant. By providing easy access to a wide range of records, these platforms have made vinyl collecting more accessible and appealing to a broader audience. The convenience and variety offered by online marketplaces have contributed to the resurgence of vinyl, making it a thriving segment of the music industry once again.

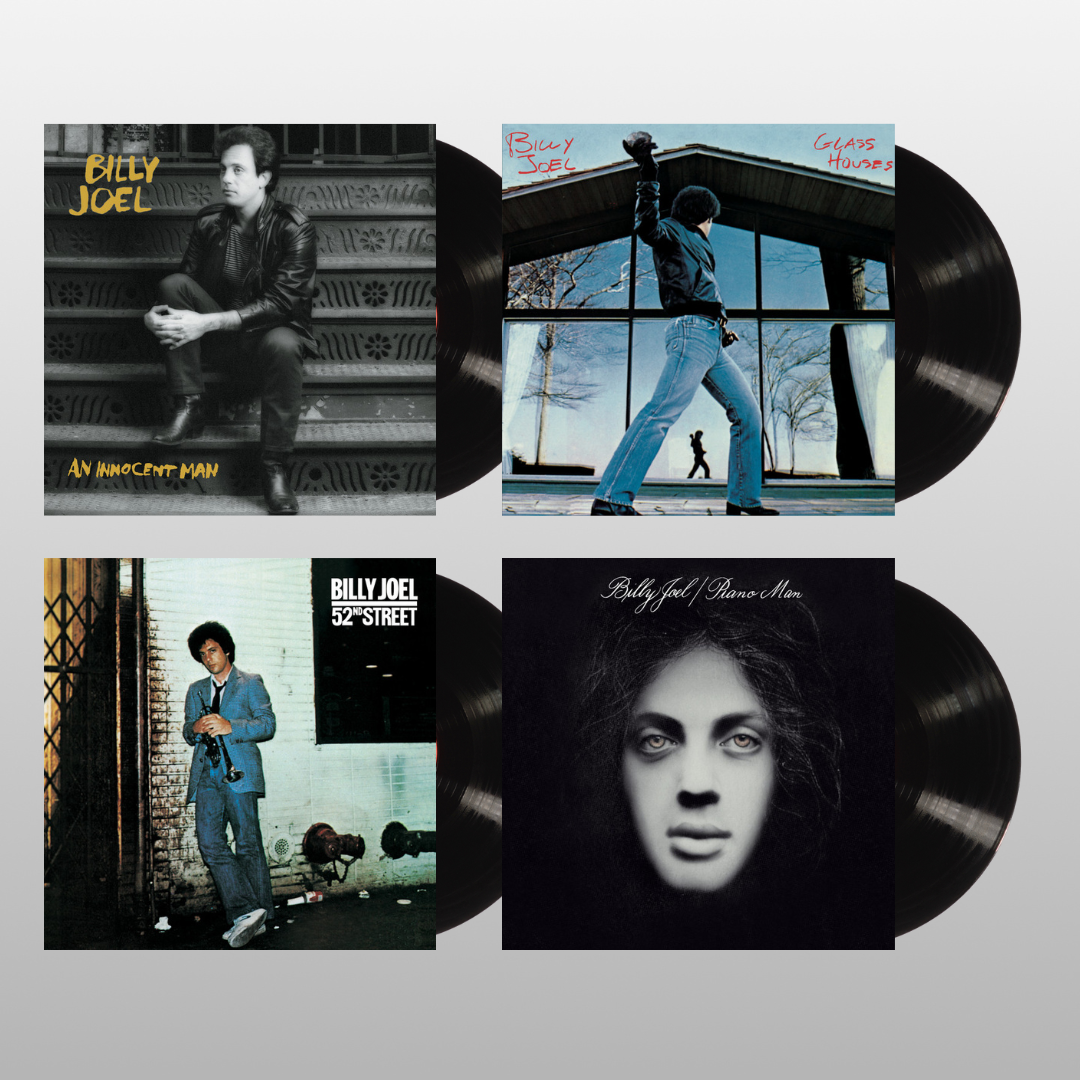

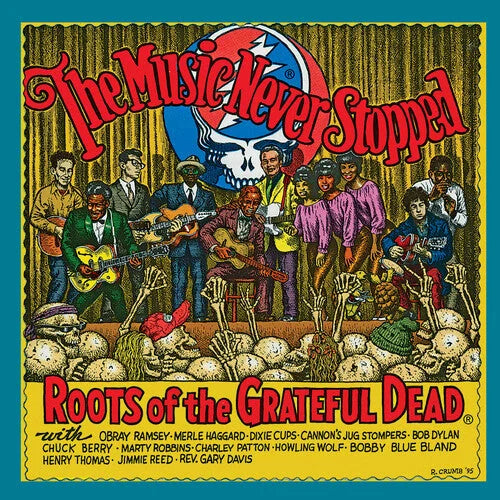

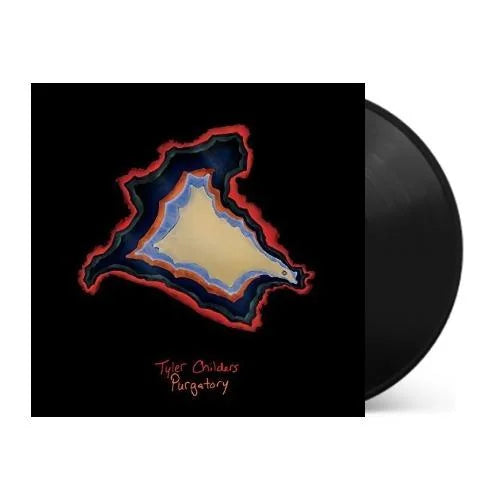

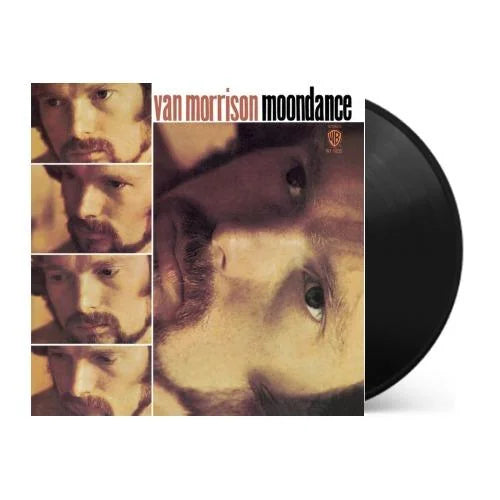

Packaging and Artwork

Beyond the creation of the vinyl itself, the production of record jackets, labels, and other packaging elements is a critical aspect of the vinyl experience. Record jackets are typically made from sturdy cardstock and are printed using either digital or offset methods, depending on the size and budget of the production run. Labels, which are baked and fused into the center of each record during pressing, are printed and die-cut in advance to ensure durability and visual appeal. Additional packaging elements may include inserts, lyric sheets, and special features like gatefold covers or die-cut designs, all contributing to the album's aesthetic and collectible value.

The vinyl record's production process is a fascinating blend of science, art, and craftsmanship. From mastering audio to cutting lacquers and pressing records, each step is essential to creating the high-quality sound that vinyl is known for. Understanding this process not only enhances your appreciation for vinyl but also deepens your connection to the music and the artists who create it. Discover new pressings, rare finds, and must-own albums by exploring Vinyl.com's full collection. As vinyl continues to thrive in the digital age, its legacy and appeal remain as strong as ever.

![Smashing Pumpkins - Mellon Collie and The Infinite Sadness [4LP Box Set]](http://vinyl.com/cdn/shop/files/MellonCollie4LP-SmashingPumpkins.png?v=1736990865&width=5760)

![The Grateful Dead - The Music Never Stopped [6LP Box Set]](http://vinyl.com/cdn/shop/files/The_Grateful_Dead-The_Music_Never_Stopped__6LP_Box_Set.jpg?v=1747729623&width=5760)

![The Grateful Dead - Madison Square Garden, New York, NY 3/9/81 (2023 Rocktober Edition) [5LP Box Set]](http://vinyl.com/cdn/shop/files/gratefuldead_2.png?v=1768197509&width=5760)

![Sufjan Stevens - Songs For Christmas [5LP Box Set]](http://vinyl.com/cdn/shop/files/3576666.jpg?v=1684195276&width=5760)

![$Uicideboy$ - Thy Kingdom Come [Clear]](http://vinyl.com/cdn/shop/files/4435583-3407920.jpg?v=1754460746&width=5760)

![(hed) p.e. - New And Improved [Pink]](http://vinyl.com/cdn/shop/files/4425252-3389420.jpg?v=1746578880&width=5760)

![1 Locate S - Wicked Jaw [Sky Blue]](http://vinyl.com/cdn/shop/files/4217742-2982879.jpg?v=1693273095&width=5760)

![Mac Miller - Swimming [2LP]](http://vinyl.com/cdn/shop/files/mac.png?v=1767598047&width=5760)

![Miles Davis - Kind of Blue [180-gram]](http://vinyl.com/cdn/shop/files/Y4LPMD03.webp?v=1742198237&width=5760)

![Taylor Swift - 1989 (Taylor's Version) [2LP Crystal Skies Blue]](http://vinyl.com/cdn/shop/files/taylor_swift_1989_taylors_version.jpg?v=1734389117&width=5760)

![Taylor Swift - folklore [2LP Beige]](http://vinyl.com/cdn/shop/files/477929-Product-0-I-637317959467683009_grande_a6f82db0-1cb7-45c5-8892-ed79af261e80.webp?v=1736750683&width=5760)

![Transformers: The Movie (Original Soundtrack) [Unicron Marbled 180-Gram]](http://vinyl.com/cdn/shop/files/4417308-3378319.jpg?v=1745982250&width=5760)

![Various Artists - The Life Aquatic With Steve Zissou O.S.T. [2LP Canary Yellow]](http://vinyl.com/cdn/shop/files/4427619-3397770.jpg?v=1747779139&width=5760)