Vinyl culture has played a pivotal role in the music industry, offering a tangible medium for music distribution that has endured despite the advent of digital formats. The allure of vinyl goes beyond mere nostalgia; it represents an era where music was an art form expressed through physical mediums. This history of vinyl records traces back to the early 20th century, highlighting technological advancements and the cultural shifts that vinyl has witnessed and influenced. Understanding this is crucial for appreciating the depth of its impact on music and its ongoing resurgence in popularity.

Early Days: The Shellac Record Era

Origins of Shellac Records in Music Distribution

Music was distributed on shellac records, a material derived from the secretion of the lac bug. This substance, combined with wax and other binders, created a playable surface for the earliest record players. Shellac was the industry standard from the late 19th century, offering the first mass-produced means of music distribution. However, these early records were brittle and prone to shattering, limiting their practicality and durability. The history of music formats owes much to these fragile beginnings, setting the stage for the more robust and enduring vinyl records that would follow.

Production Methods and Material Characteristics

Shellac's record history is marked by its unique production methods. The material was sourced mainly from Southeast Asia, where it was harvested, processed, and shipped to worldwide record manufacturing hubs. In these factories, shellac was melted, mixed with fillers like slate dust and carbon black, and then pressed into disc shapes using steam-powered machinery. The characteristics of shellac made it less ideal for preserving sound fidelity; its rigid structure often led to a higher rate of wear and more surface noise during playback. Despite these challenges, shellac dominated the market due to the lack of better alternatives at the time.

Sound Quality and Limitations of Shellac

Listeners often noted the hissing and popping noises that were common with shellac records, a byproduct of the material's texture and the wear from the heavy playback needles then in use. Also, shellac records could only hold approximately three to five minutes of music per side, a constraint that shaped the early music industry, influencing everything from the length of songs to the structure of musical compositions. This period in analog music history highlighted the need for a more advanced medium that could offer more precise sound and longer playback.

Shaping Early Music Formats

It was the vehicle through which many classical and early popular recordings were made accessible to the public. The format constraints led to the standardization of song lengths and the structuring of musical outputs to fit the limited recording capacity. This era laid the groundwork for the evolution of vinyl, which would eventually address many of the shortcomings of shellac records.

Transitioning from Shellac to Vinyl

Reasons for the Shift to Vinyl Materials

This shift was largely driven by the need for a more durable, flexible, and higher-fidelity medium. Vinyl, made primarily from polyvinyl chloride (PVC), emerged as a superior choice due to its ability to withstand repeated playbacks without significant degradation in sound quality. This fundamental change was a technical improvement and a transformation in how music could be enjoyed and preserved.

Improvements in Durability and Sound Fidelity

Unlike shellac, vinyl could flex without breaking, reducing the risk of damage during transport or normal handling. This resilience extended the life of records, providing better value and a more satisfying user experience. The smoother surface of vinyl also allowed for more precise groove etching, enhancing the nuances and clarity of the recorded sound. Such an upgrade in sound reproduction capabilities made vinyl a preferred medium for audiophiles and casual listeners.

Early Adoption and Industry Response to Vinyl

Initially used for special-edition releases or for albums requiring superior sound quality, vinyl soon became the standard for all types of music recordings. The industry's response was overwhelmingly positive, as vinyl offered a better product and sparked a wave of re-releases of classic albums, now remastered to take advantage of vinyl's superior sound properties.

Technological Advancements in Vinyl Production

Innovations in Pressing Techniques

Vinyl technology has seen significant advancements in pressing techniques since its inception. Innovators in the field developed hydraulic and steam-powered presses that could handle the more malleable vinyl with greater precision than the older equipment used for shellac. These modern machines allowed for faster production cycles and more consistent quality of the final product. The introduction of automated systems further revolutionized the pressing process, enabling manufacturers to increase output while maintaining the integrity of the sound recorded on each disc. This evolution played a crucial role in meeting the growing demand for vinyl records during the music industry's boom periods.

The Impact of Improved Machinery on Record Quality

The implementation of improved machinery had a direct impact on the quality of vinyl records. Advanced pressers and cutting lathes offered a higher level of precision, which significantly reduced the occurrence of manufacturing defects such as warping or surface noise. This enhancement in production technology ensured that the rich, authentic sound of analog music was captured more faithfully on vinyl, satisfying the stringent requirements of audiophiles and professional musicians alike. These technological improvements underscored vinyl's superiority over previous formats, cementing its place in the history of limited vinyl pressings.

Advances in Materials and Production Efficiency

While vinyl once faced challenges related to pressing inconsistencies and environmental concerns, modern innovations have drastically improved the durability, sound fidelity, and sustainability of record production. These technological improvements have made vinyl records more appealing to audiophiles and collectors, reinforcing their status as a premium music format. Below are some of the key advances:

- Precision Engineering: The refinement of precision engineering techniques has significantly enhanced the quality of vinyl history, reducing common pressing defects and inconsistencies. Modern pressing plants utilize computer-controlled hydraulic presses that regulate factors such as temperature, pressure, and cooling time with extreme accuracy. This precision ensures that records are consistently pressed with the correct groove depth and spacing, which minimizes errors such as non-fill (where grooves don’t fully form) or off-center pressing (which causes pitch instability). High-precision lathes are used during the mastering process to cut lacquer discs with greater accuracy, preserving the nuances of an artist’s original recording.

- Efficient Production Lines: Today’s pressing plants utilize computer-aided manufacturing (CAM) systems, which monitor every step of production in real time, adjusting parameters to optimize consistency. These systems allow for faster turnaround times and reduced waste, enabling record labels to produce high volumes of records while maintaining strict quality control. Innovations such as direct-metal mastering (DMM) help reduce production time by eliminating the need for traditional lacquer-based master discs, resulting in a sharper and more durable groove. These efficiencies have allowed vinyl production to scale up to meet increasing demand, making it possible for independent artists and major labels to release records more affordably and reliably than in previous decades.

- Environmental Considerations: While vinyl records are traditionally made from petroleum-based materials, advancements in sustainable production methods have made the process more eco-friendly. Many pressing plants now focus on recycling vinyl trimmings and leftover materials, reducing waste and minimizing the need for new raw resources. Some manufacturers have also experimented with bio-based vinyl compounds, which aim to decrease reliance on fossil fuels while maintaining high audio fidelity. Improvements in energy-efficient pressing machines have reduced the overall carbon footprint of record production. Some plants have even transitioned to solar-powered operations, further minimizing environmental impact.

As technology continues to improve, the vinyl industry will likely see even greater innovations, ensuring that this beloved format remains relevant in an era dominated by digital music. By balancing tradition with cutting-edge manufacturing techniques, vinyl continues to offer music enthusiasts a rich, immersive listening experience that stands the test of time.

Evolution of Vinyl Record Production Techniques

From Mass Production to Precision Engineering

Early vinyl was often produced with a one-size-fits-all approach, which did not account for the intricacies of different musical styles or the nuanced demands of audio fidelity. However, as the market for vinyl grew and the expectations of listeners became more sophisticated, the production processes evolved. Manufacturers began implementing more refined techniques that could cater to the specific acoustic properties required by different genres of music.

Refinement of Cutting and Pressing Processes

The advent of computer-controlled cutting lathes brought a level of precision previously unattainable. This significantly reduced errors and inconsistencies in the grooves, which in turn improved sound clarity and detail.

- Laser-Guided Cutting Tools: Traditional cutting lathes depended on mechanical movements that, despite their efficiency, could introduce minor inconsistencies in groove depth and width. With laser technology, each groove is formed with exact precision, minimizing distortion and ensuring optimal tracking by the stylus. This advancement significantly enhances sound fidelity, allowing for clearer instrument separation and more detailed audio reproduction. Laser-guided systems reduce the risk of human error, ensuring that every master record is cut to the highest standard.

- Thermal Regulation Systems: Vinyl is a thermoplastic material, meaning that variations in heat levels can lead to defects such as warping, uneven surfaces, and groove distortion. To combat these issues, modern pressing plants have adopted sophisticated thermal regulation systems that maintain precise temperatures throughout the production process. These systems ensure that the vinyl material remains at the optimal softness for molding while cooling at a controlled rate to prevent shrinkage or deformations. Advanced heating and cooling mechanisms have also reduced the risk of surface irregularities, allowing for a smoother and more durable finish. This refinement has been essential for mass production, as it minimizes defects while maintaining the integrity of each record.

- Pressure Calibration: Applying the correct amount of pressure during the pressing stage is vital to achieving flawless vinyl records. If the pressure is too high, the grooves can become overly compressed, affecting the dynamic range of the audio. On the other hand, insufficient pressure can result in non-fill defects, where the vinyl fails to spread evenly into the mold, leading to gaps and distortions in the grooves. To address this, modern pressing plants use precision-calibrated hydraulic presses that apply uniform pressure to each record, ensuring that grooves are properly formed and audio details are preserved.

- Quality Control Protocols: Stringent quality control measures have become standard practice in vinyl record production, ensuring that every pressing meets high industry standards before reaching consumers. In the past, inconsistencies in the production process led to defects that were often detected only after records were sold. Today, manufacturers implement multiple inspection checkpoints, including visual groove analysis, weight verification, and test pressings to identify potential flaws before mass distribution. Automated scanning technology can detect minute errors, such as off-center grooves or excessive surface noise, allowing for immediate adjustments. These measures have significantly reduced the number of defective records reaching the market, enhancing overall customer satisfaction.

With these advancements, the process of vinyl record manufacturing has become more refined than ever before. These refinements will play an essential role in meeting the demands of audiophiles and collectors who value superior sound quality and craftsmanship.

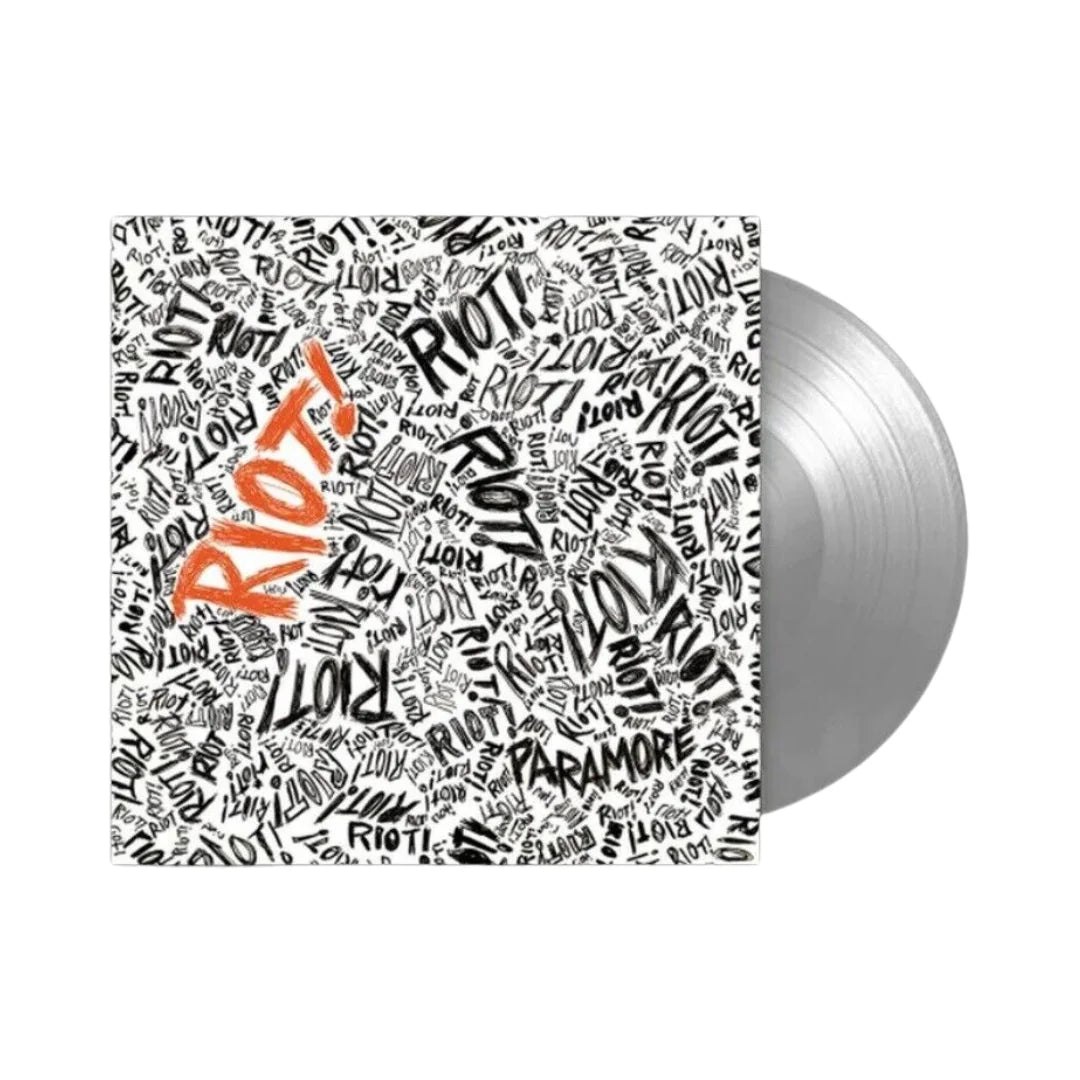

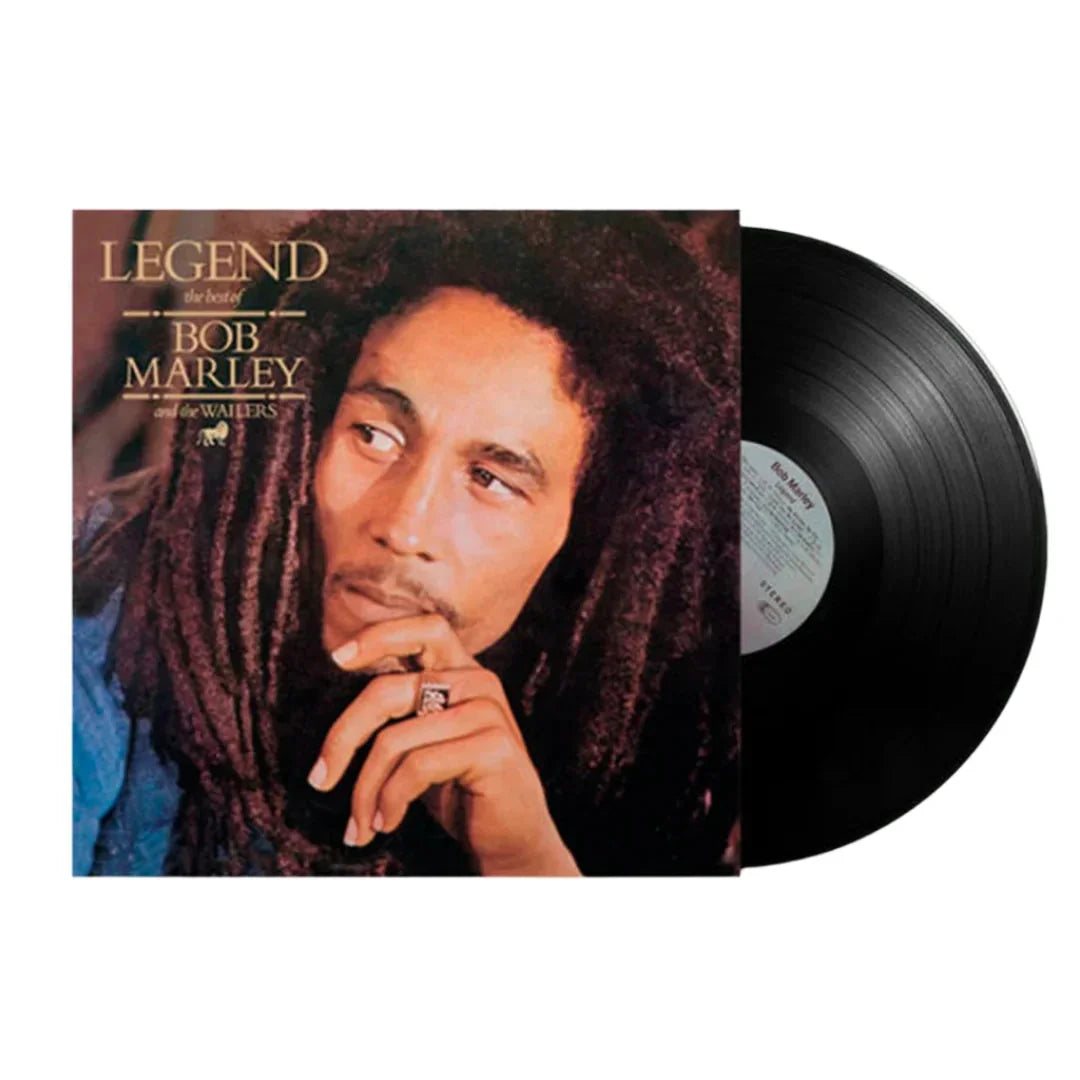

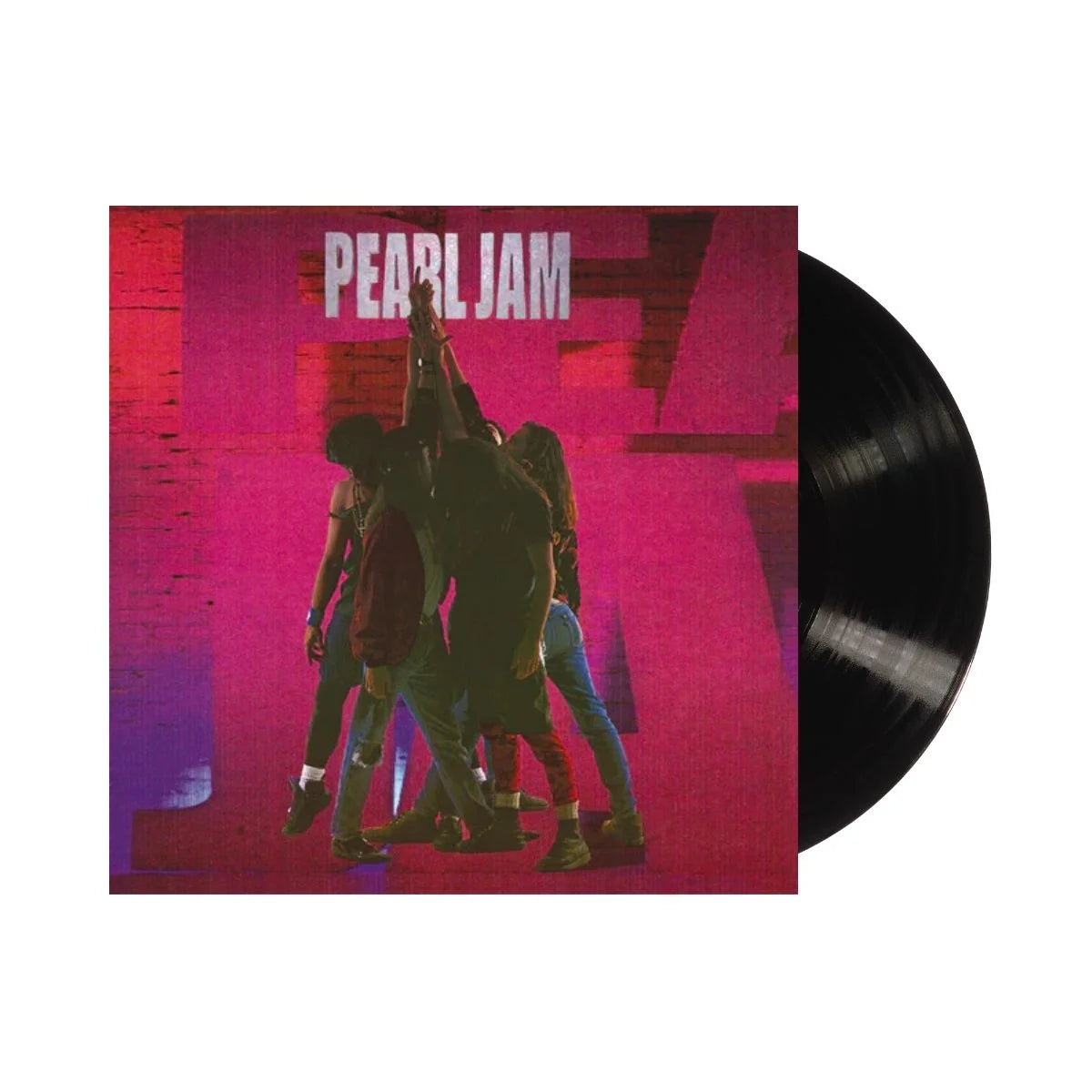

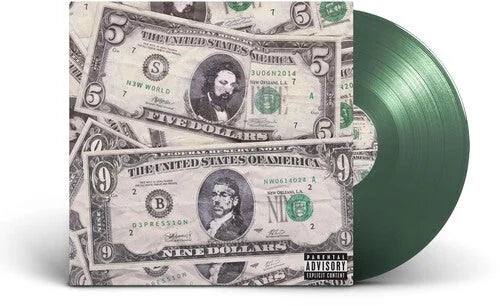

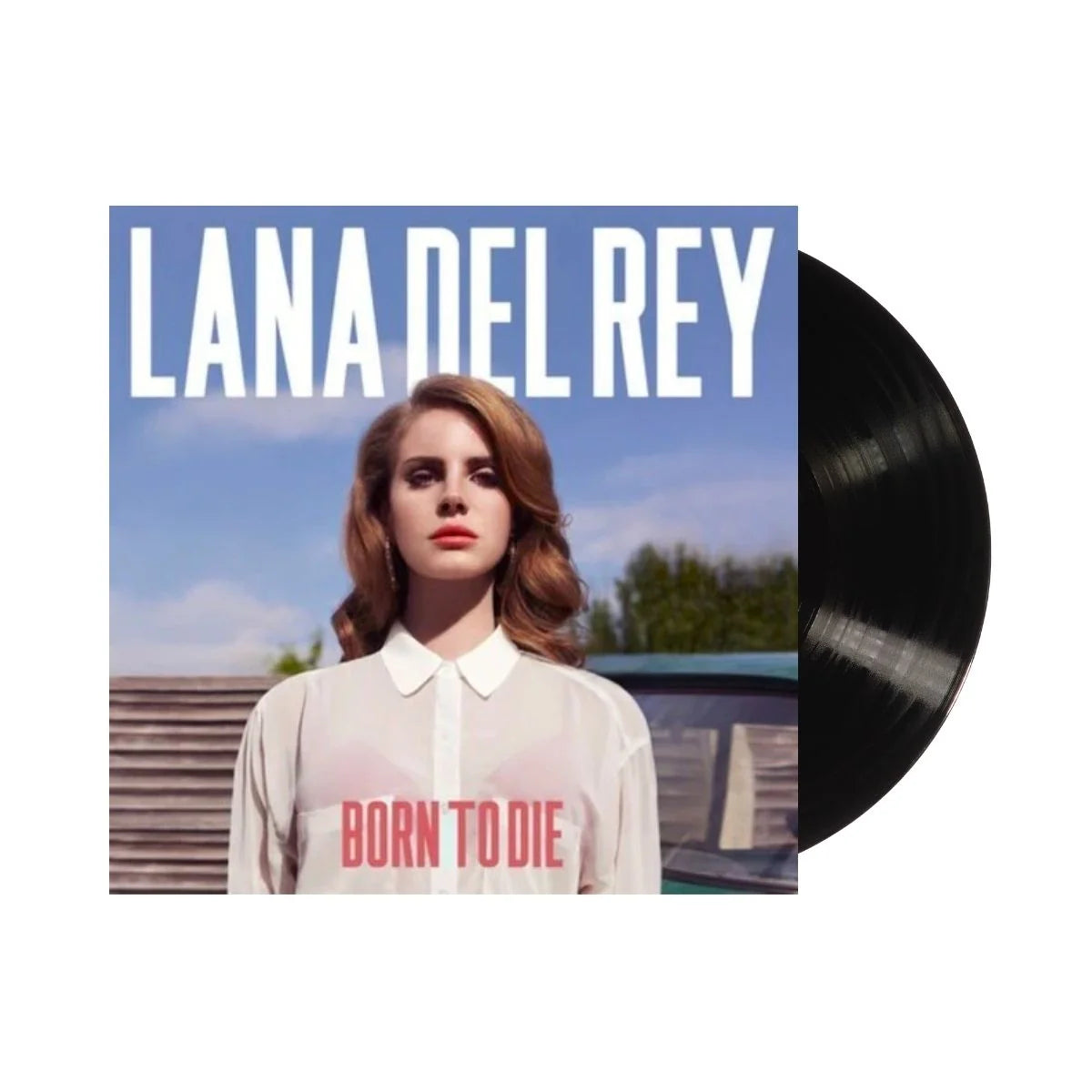

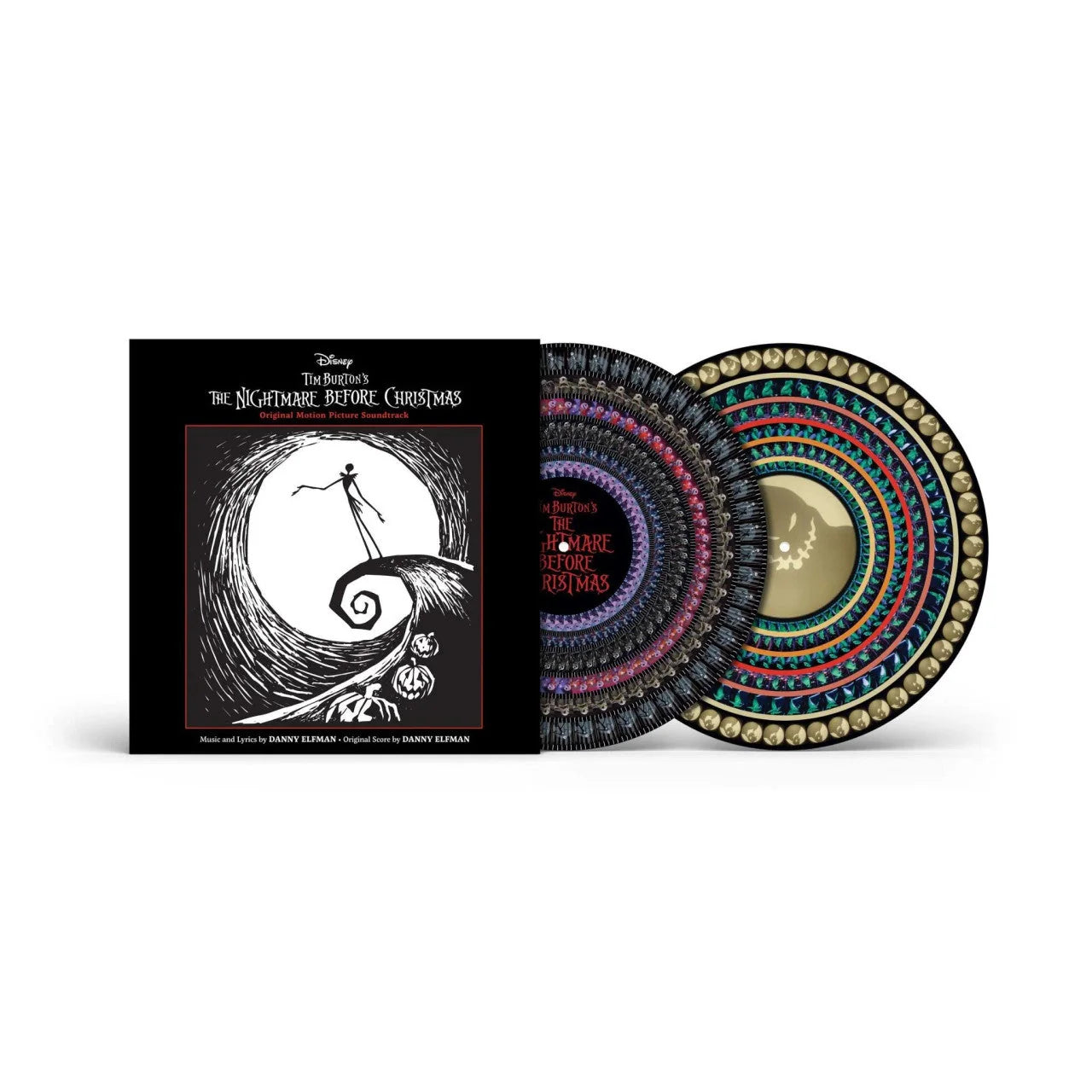

The Emergence of Collectible Vinyl

How Vinyl Became a Collector’s Item

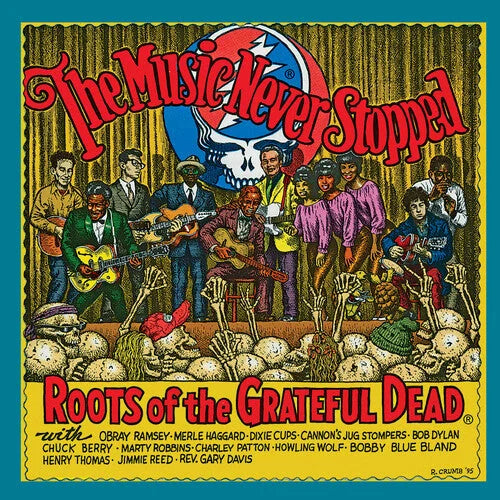

Album artwork, special edition releases, and the physical tangibility of vinyl all contributed to its allure as an item worth collecting. As music consumption shifted with the advent of digital media, vinyl records began to represent a nostalgic and authentic music experience, increasing their value and desirability among enthusiasts. Collectors and music fans started to cherish vinyl not only for the music it carried but also for its cultural and aesthetic significance.

Key Milestones in Vinyl Record Collecting History

This music media evolution has several key milestones that underscore the growing appeal of vinyl as a collector’s medium. The release of limited edition albums, often featuring unique artwork and rare recordings, helped cement vinyl’s position in music collectibles. Reissuing classic albums in vinyl format, sometimes remastered with superior sound quality or featuring bonus content, has continually regenerated interest and excitement in vinyl collecting.

The Marketing Impact of Scarcity in Vinyl Releases

Record labels and artists use scarcity as a tool to generate buzz and excitement, drawing attention not only from hardcore collectors but also from casual fans. This marketing strategy has revitalized the vinyl industry, making record release days significant events anticipated and celebrated within the music community. The hype surrounding modern vinyl limited pressings often leads to immediate sell-outs, which boosts sales and fosters a vibrant resale market, adding another layer of engagement in the vinyl collecting culture.

The historical vinyl collecting movement and the sustained interest in vinyl record websites and online communities underscore ongoing relevance. As we look to the future, vinyl appears poised to continue its legacy, resonating with older generations who cherish its nostalgia and younger audiences who discover its unique charm. Their enduring appeal assures that they will remain an essential part of our musical and cultural lexicon for years to come, celebrating the undying spirit of analog music in a digital world.

![The Grateful Dead - The Music Never Stopped [6LP Box Set]](http://vinyl.com/cdn/shop/files/The_Grateful_Dead-The_Music_Never_Stopped__6LP_Box_Set.jpg?v=1747729623&width=5760)

![The Grateful Dead - Madison Square Garden, New York, NY 3/9/81 (2023 Rocktober Edition) [5LP Box Set]](http://vinyl.com/cdn/shop/files/4247396-3042523.jpg?v=1758034700&width=5760)

![Sufjan Stevens - Songs For Christmas [5LP Box Set]](http://vinyl.com/cdn/shop/files/3576666.jpg?v=1684195276&width=5760)

![(hed) p.e. - New And Improved [Pink]](http://vinyl.com/cdn/shop/files/4425252-3389420.jpg?v=1746578880&width=5760)

![1 Locate S - Wicked Jaw [Sky Blue]](http://vinyl.com/cdn/shop/files/4217742-2982879.jpg?v=1693273095&width=5760)

![11/5 - A-1 Yola [2LP Orange Swirl]](http://vinyl.com/cdn/shop/files/3992138-2728122.jpg?v=1684200429&width=5760)

![Zach Bryan - American Heartbreak [3LP]](http://vinyl.com/cdn/shop/files/Zach_Bryan-American_Heartbreak_3LP.webp?v=1764838852&width=5760)

![Transformers: The Movie (Original Soundtrack) [Unicron Marbled 180-Gram]](http://vinyl.com/cdn/shop/files/4417308-3378319.jpg?v=1745982250&width=5760)