For new collectors, understanding the types of vinyl pressings is crucial as it greatly influences both the aesthetic value and the potential investment of the records. Each variant, whether it’s a limited edition vinyl pressing or a color variant, can hold a distinct appeal due to its rarity, design, and manufacturing process. By comprehending these differences, collectors can make more informed choices about what adds value to their collection, ensuring they do not just purchase records but invest in pieces that accrue value and significance over time.

The Vinyl Record Pressing Process Explained

How Vinyl Records Are Pressed

The art and science of pressing vinyl records is an intricate process that combines precise engineering with creative flair. Below are key steps:

- Preparation of Vinyl Pellets: Manufacturers choose pellets for their exceptional durability and superior acoustic qualities, ensuring that every record produced meets rigorous performance standards. These can be formulated in various colors, ranging from translucent hues to deep, rich tones, allowing for both standard and collectible editions. The selection process involves a careful review of the vinyl’s composition and properties, as even minor variations can influence the final sound quality and appearance. Once the best pellets are chosen, they are meticulously cleaned and measured to ensure consistency throughout the production run. Specialized equipment is employed to sift through and eliminate any impurities or irregularities that might affect the molding process. This stage is critical because any flaws in the raw material can lead to audible defects or visual inconsistencies in the final product.

- Heating and Molding: Once the vinyl pellets are prepared, they undergo a precise transformation through heating and molding. In this phase, the pellets are subjected to controlled temperatures that melt them into a pliable, homogenous mass. This molten material is then carefully transferred into a molding system where it forms what is colloquially known as a “biscuit” or “puck.” The temperature, pressure, and duration of heating are all meticulously regulated to ensure that the vinyl achieves the ideal consistency required for detailed imprinting. During molding, the softened vinyl is shaped to exact dimensions, providing a uniform base that will later capture the intricate grooves of the audio recording. Operators monitor the process closely, as even slight deviations in heat or pressure can result in imperfections that affect sound quality. This also involves a brief period where the puck can settle, ensuring that the internal structure is consistent throughout. The care taken in heating and molding is crucial, as it lays the groundwork for stamping by ensuring the vinyl’s physical properties are optimized for high-fidelity sound reproduction and longevity.

- Stamping: With the molded vinyl puck ready, the next critical step is stamping, where the actual grooves are imprinted to form the record’s surface. Stamping begins by aligning the puck between two halves of a meticulously crafted stamper. This stamper contains a mirror image of the audio grooves, which have been etched onto it through a series of master recordings and electroplating techniques. Under high heat and pressure conditions, the stamper compresses the vinyl, causing the delicate grooves to be transferred in precise detail. During this phase, the careful calibration of pressure and temperature is essential, as it directly influences the sound's clarity and the grooves' depth. Operators vigilantly monitor the cycle to ensure that the pressing is consistent and free from defects such as warping or incomplete imprinting. The stamping process is a moment of transformation, where the intangible sound is translated into a physical form that can be appreciated through analog playback.

- Cooling and Solidification: Immediately following the intense heat of the pressing stage, the record is rapidly cooled to lock in the grooves and maintain the precise contours of the sound imprint. This rapid cooling is typically achieved through specialized cooling units that use controlled airflow or water baths to quickly and uniformly reduce the temperature. The objective here is to ensure that the vinyl solidifies without any distortion, preserving the sharpness of the audio details. During this period, the record transforms as the softened vinyl crystallizes into its final, robust form. The cooling process is carefully timed to balance speed and consistency, as premature or uneven cooling can lead to warping or microfractures in the vinyl. Technicians inspect the records as they exit the cooling stage, checking for any signs of surface irregularities that might affect playback quality.

- Quality Checks and Finishing: After cooling, every record is carefully inspected by trained technicians who search for any imperfections such as surface defects, misaligned grooves, or visual inconsistencies. This rigorous quality check is vital in identifying issues that could compromise the audio experience or the record’s durability. Once approved, the records move on to the finishing phase, where excess vinyl is trimmed from the edges to create a clean, uniform appearance. At this point, labels are precisely applied to the center, adding functional information such as track listings and artist details and contributing to the overall visual appeal. Additional treatments, such as protective coatings or specialized packaging for collector’s editions, may be applied to enhance durability. The finishing touches are a testament to the blend of art and precision that defines vinyl record production.

Each phase in the vinyl pressing process is a testament to the meticulous craftsmanship and technical expertise required to produce high-quality records.

Key Roles of Vinyl Record Manufacturers

Vinyl pressing companies play critical roles in the lifecycle of a vinyl record. From overseeing the initial audio mastering to managing the complex pressing process, these entities ensure that the artistic vision of musicians is translated into physical form with high fidelity. Their expertise in handling the delicate materials and machinery involved in custom vinyl record pressing and mass production is indispensable in maintaining the resurgence of vinyl in today's digital age. Custom ones often concern smaller run sizes, allowing for greater customization in aspects like color and design, making it ideal for independent artists or limited releases. In contrast, mass production is suited for larger volumes, utilizing standardized processes to achieve cost efficiency and consistency, crucial for major record labels.

Vinyl Record Printing and Production Techniques

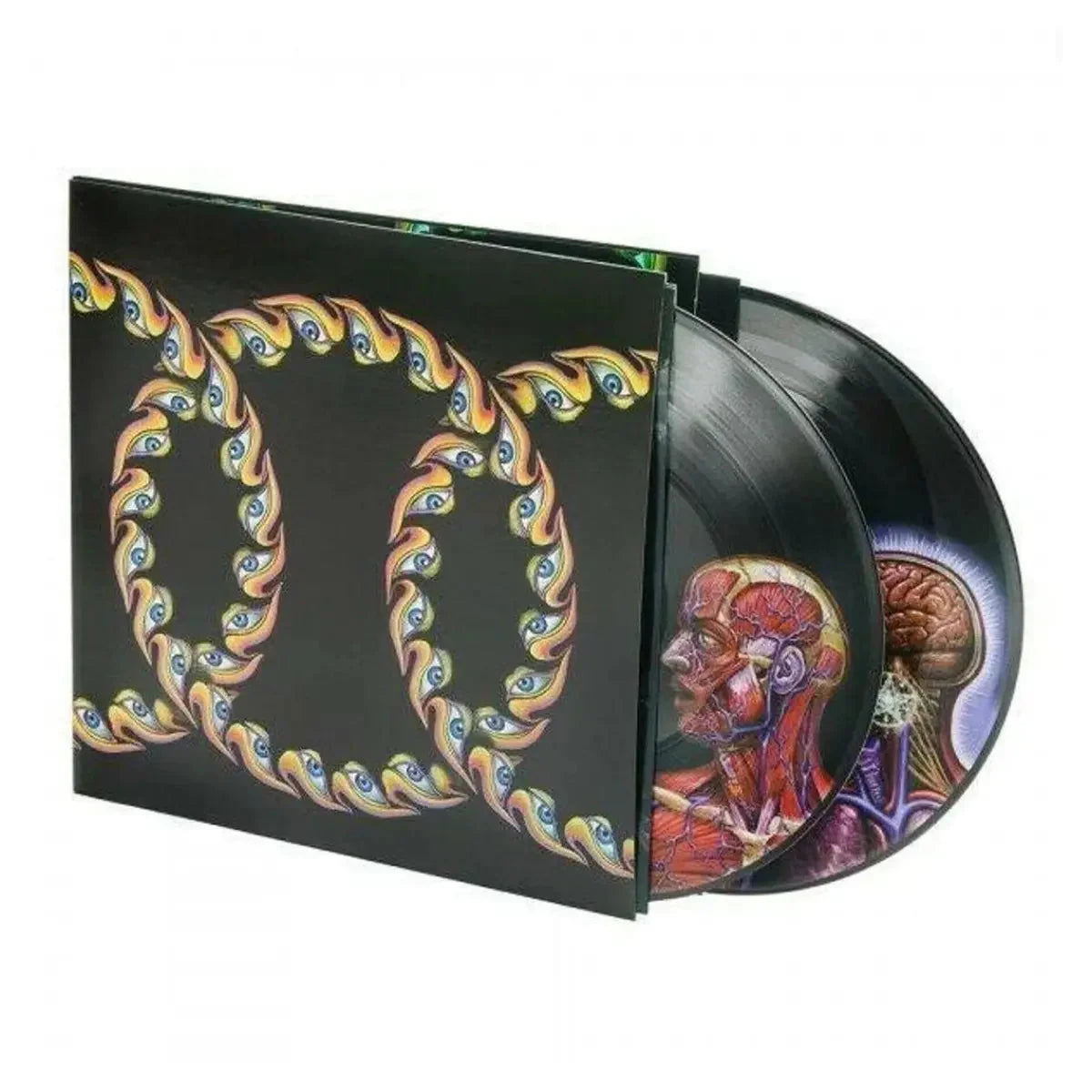

Techniques such as picture disc vs. colored vinyl production involve different materials and processes that cater to aesthetic preferences while potentially affecting playback quality. Understanding these techniques helps discern between a vinyl pressing for collectors and choose the right variants to match their aesthetic and auditory preferences.

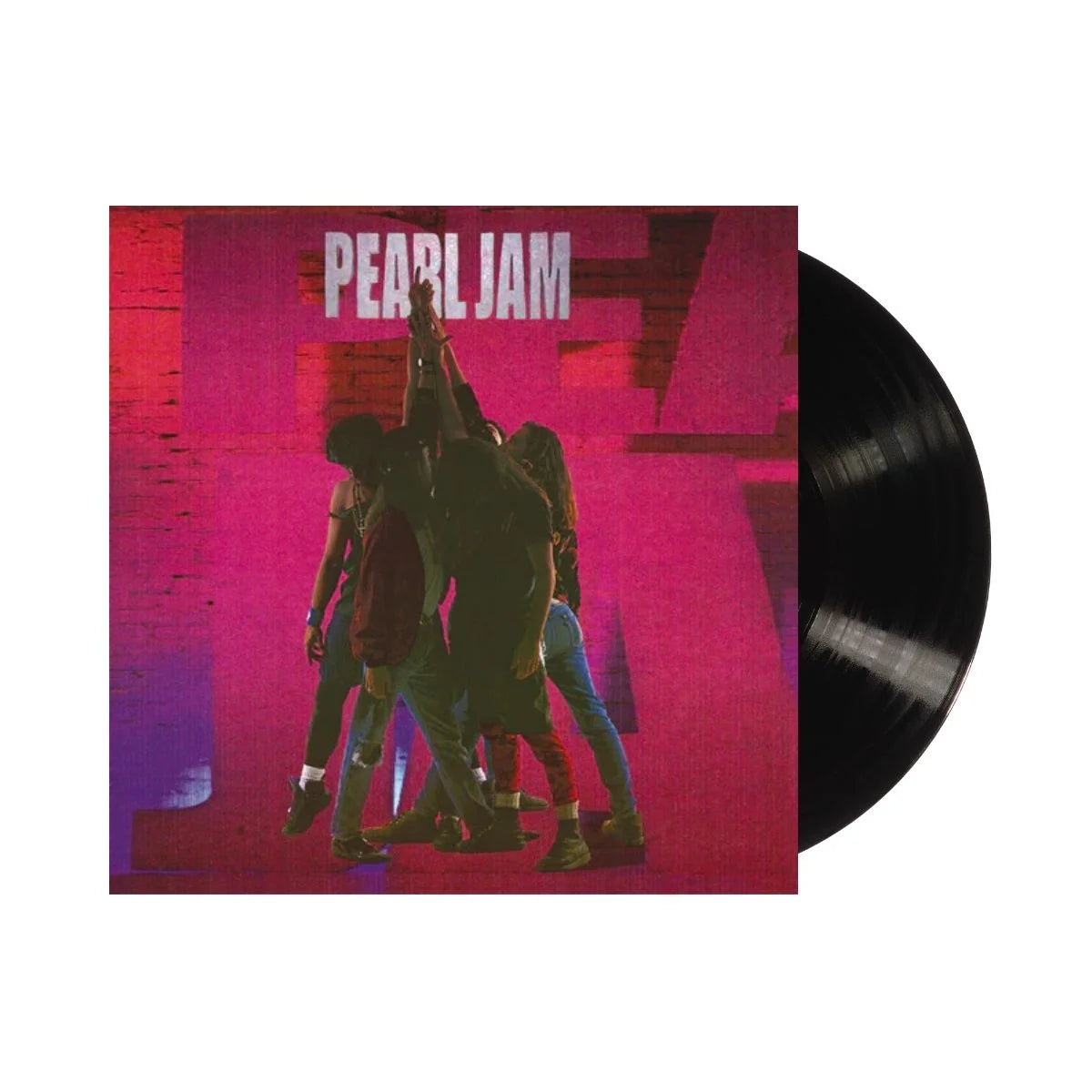

Exploring the Different Types of Vinyl Pressings

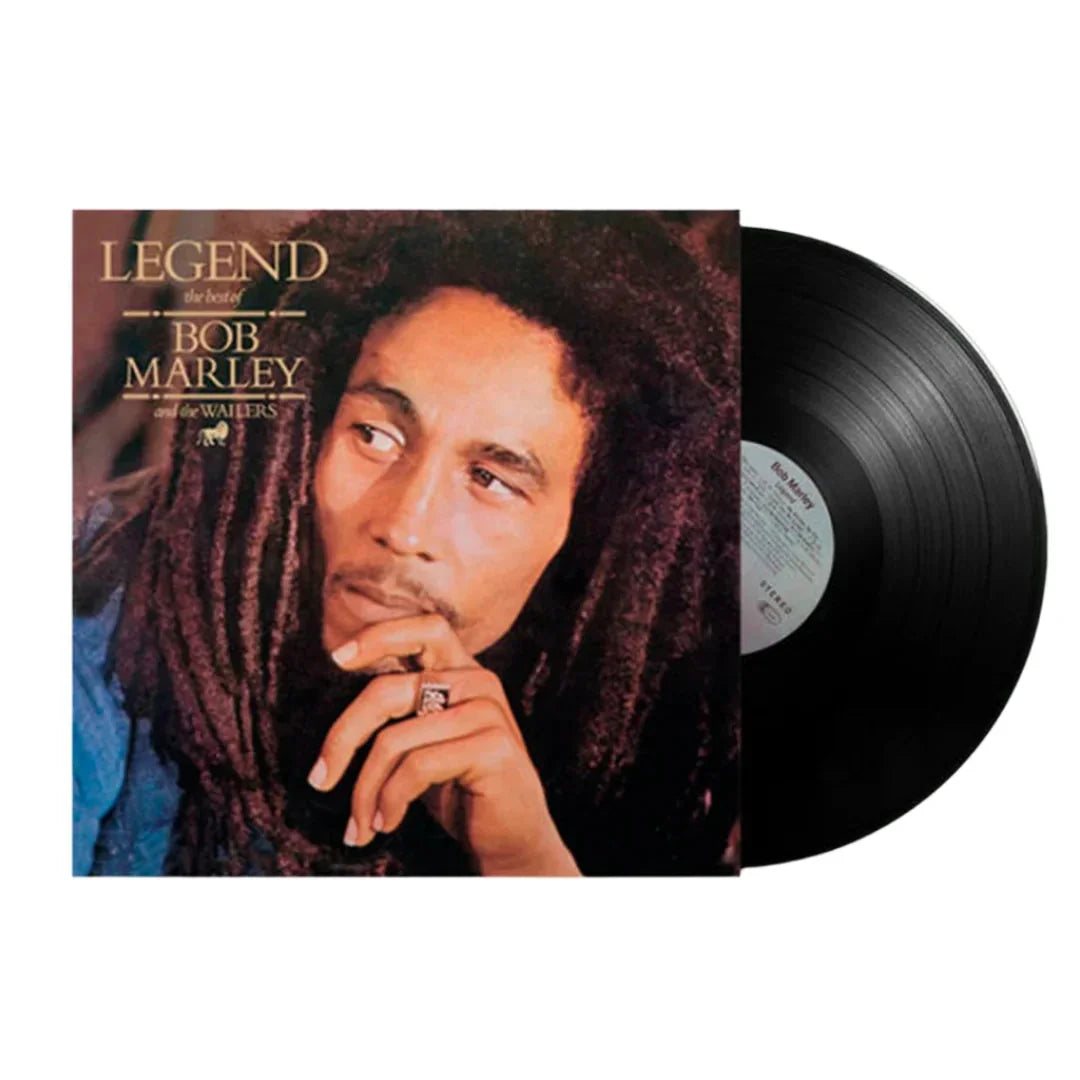

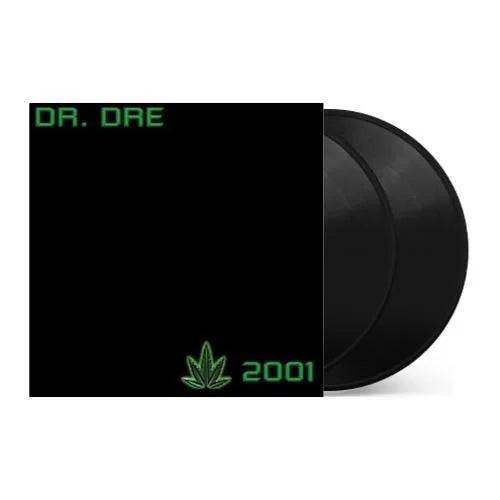

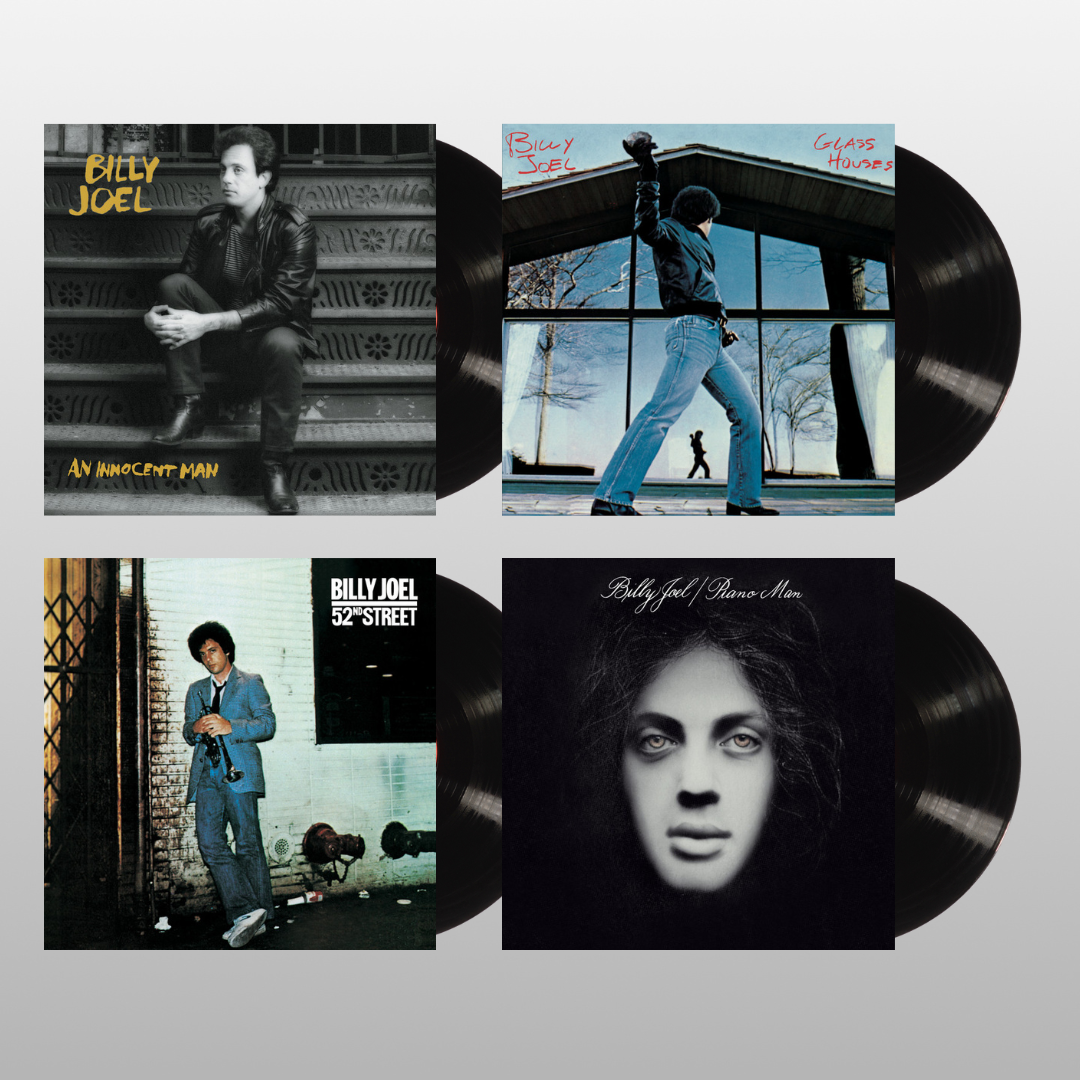

Standard vs. Limited Edition Vinyl Pressings

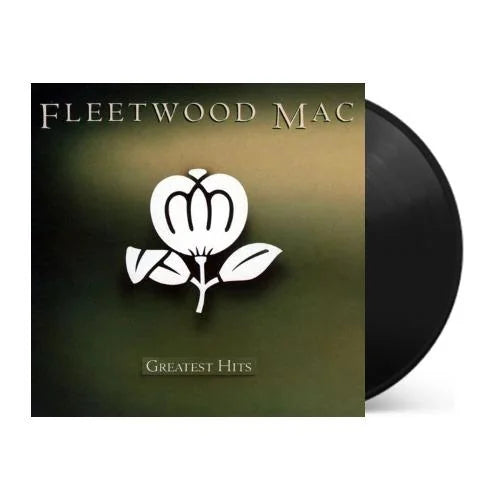

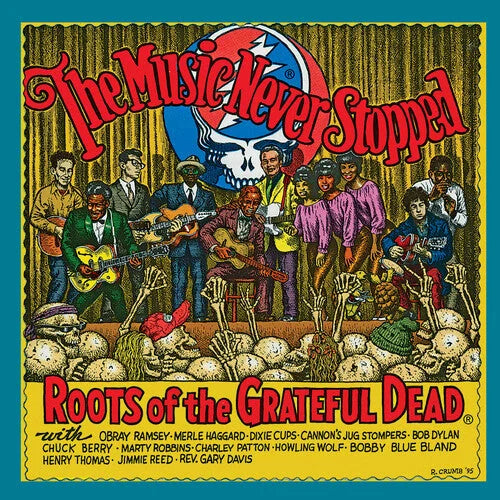

Standard vinyl pressings are the most common type available and are produced in larger quantities. These editions typically feature the traditional black vinyl and are intended for widespread distribution. In contrast, limited editions are produced in smaller quantities and often come with unique features like colored vinyl, special artwork, or additional content such as posters or booklets. These are highly prized among collectors for their exclusivity and potential to appreciate in value over time.

Exclusive Vinyl Press Run Types

It offers something unique that can't be found in standard pressings, such as autographed sleeves, alternative cover art, or vinyl in rare colors. Such pressings are often released through specific outlets or events, enhancing their desirability and collectibility. They not only serve as a means of owning a piece of music history but also as a way to express personal taste and dedication to a particular artist or genre.

Small Batch Vinyl Pressing for Indie Artists

It allows musicians to release their records in physical form without the hefty investment required for large press runs. For collectors, small batches mean the chance to own a rare piece of music that few others have, often with high levels of craftsmanship and attention to detail. These pressings help foster a closer connection between artists and their audience, making each record feel more personal and valued.

Comparing Different Vinyl Pressing Formats

From the standard 12-inch LP to the smaller 7-inch singles and even the less common 10-inch records, each format has its place. LPs are favored for albums due to their capacity to hold more music, while singles are great for collectors focused on specific songs or for DJs who value the ease of handling more minor records. Comprehending these formats helps enthusiasts and collectors select the best type for their listening habits and collection goals.

Color Variants in Vinyl Records

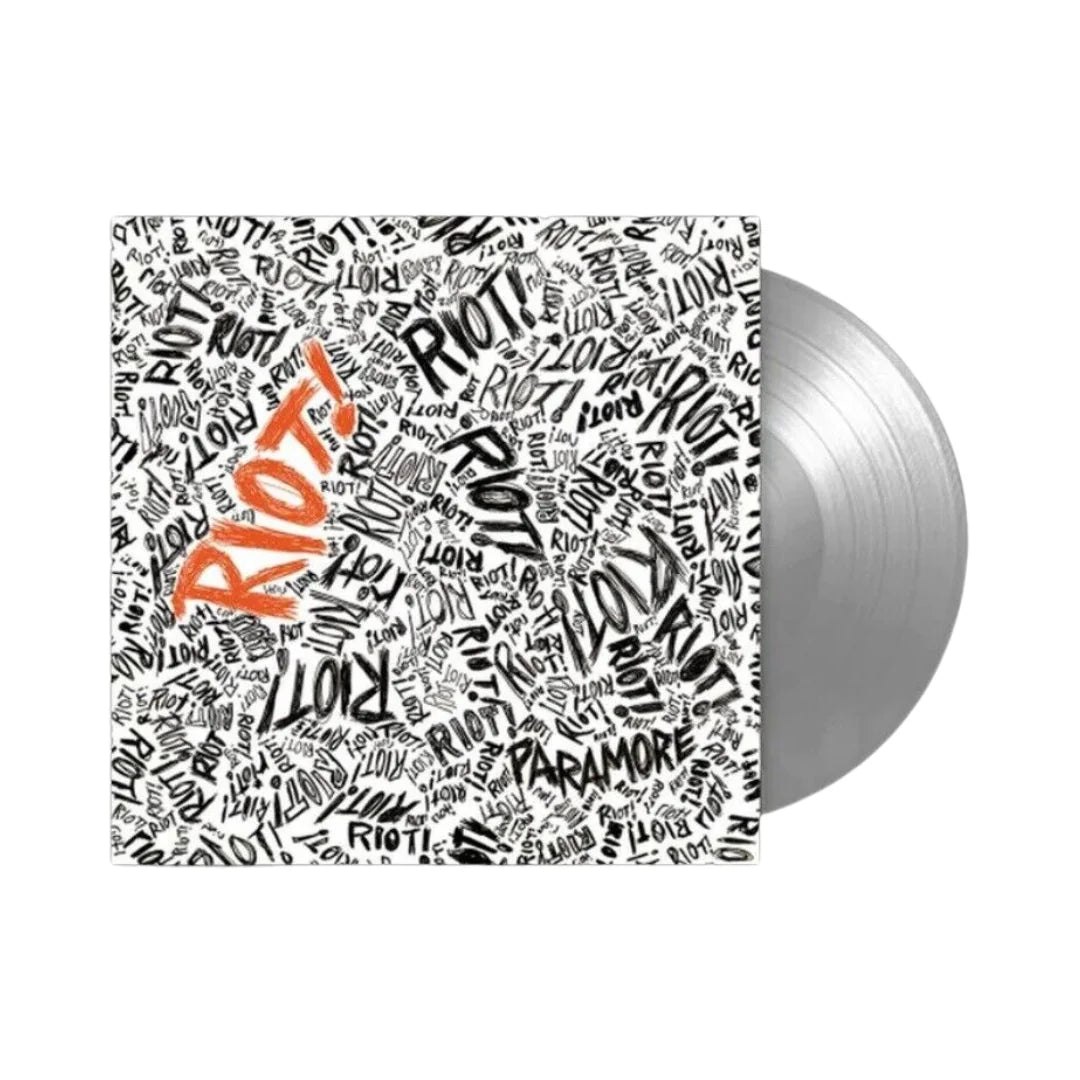

Transparent Vinyl vs Opaque Vinyl

Transparent vinyl is prized for its sleek, modern appearance and the way it showcases the intricacies of the vinyl itself. Opaque vinyl is typically more forgiving of imperfections during the pressing process, potentially resulting in a cleaner playback. Collectors often choose based on the visual appeal or the artist's intent behind the record design.

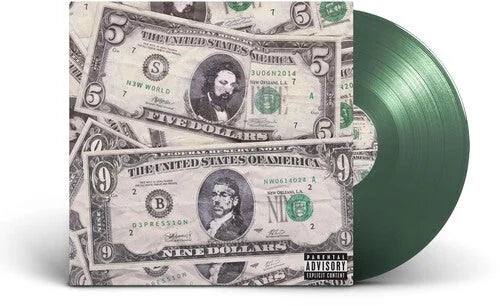

Marbled Vinyl Record Variants

This variant is particularly popular among collectors who value the aesthetic aspect of vinyl records. The marbling effect is achieved by mixing different colored pellets before pressing, meaning no two records are identical. This uniqueness adds a significant artistic value to each copy, enhancing its appeal and collectability.

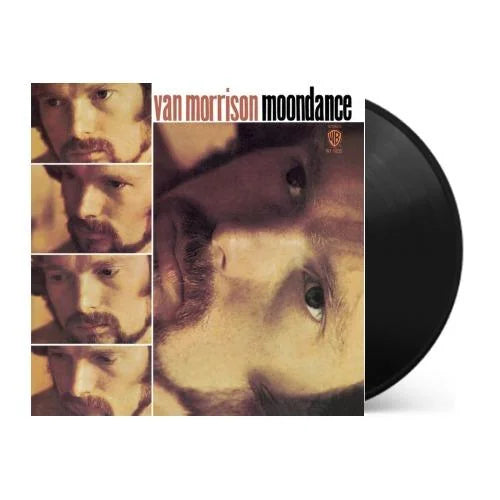

Understanding Vinyl Weight and Sound Quality

Vinyl Weight Options

When discussing vinyl weight and sound quality, numbers like 120g or 180g refer to the weight of the record, which directly impacts both durability and acoustic performance. Audiophiles typically prefer heavier vinyl for its ability to reduce resonance and provide a more stable rotation, leading to a cleaner and richer sound. However, heavier does not always mean better, as the quality of the mastering and the pressing process are also critical factors in the audio outcome.

How Vinyl Weight Affects Durability and Playback

Heavier vinyl records are less prone to warping and tend to handle the wear of repeated playbacks better than their lighter counterparts. The added mass provides a more solid feel, offering less susceptibility to vibrations and external interferences that can distort sound. It makes heavy vinyl popular among serious collectors and music enthusiasts who value long-term preservation and consistent audio quality.

Collecting and Purchasing Vinyl Records

Where to Buy Vinyl Records Online

The convenience of purchasing vinyl records online has made it easier for collectors to expand their libraries. However, it is crucial to navigate this space cautiously to avoid counterfeit products or poor-quality pressings. Trusted online platforms that verify the authenticity of their goods and provide detailed descriptions and reviews are indispensable. Additionally, engaging with community forums and social media groups can offer insights and recommendations on reliable online vinyl shops.

How to Order Vinyl Records Directly from Pressing Companies

Many of these companies offer pre-order options for upcoming releases, ensuring enthusiasts can secure copies before the public release. A direct approach not only supports the artists and producers but also cuts down on potential issues related to handling and shipping that can affect the records’ condition.

Tips for Purchasing Exclusive Pressings

Collecting limited edition and exclusive vinyl pressings is thrilling but requires strategy and attentiveness. Here are key tips to enhance your collecting experience:

- Stay Informed: Information is power, and subscribing to newsletters and following social media accounts of your favorite artists and record labels can give you an edge over other collectors. By actively monitoring these channels, you become part of an exclusive network that receives early alerts on limited runs, pre-sale events, and exclusive collaborations. This proactive approach helps you stay updated and allows you to plan your budget and schedule around release dates. In addition, engaging with online forums and fan communities can provide supplementary insights, offering you perspectives on potential reissues, special variants, or artist-specific pressings that might not be widely publicized.

- Act Quickly: As soon as a release is announced, it is vital to be ready to act without hesitation. Many collectors face the frustration of missing out due to delays in decision-making or technical issues during the purchase process. To combat this, ensure that you have all your purchasing details set up in advance, such as account information and payment methods, to streamline the checkout process. Consider creating alerts or reminders on your phone or calendar to signal the exact moment when the sale goes live. Quick action often determines whether to obtain a coveted prize or watch it vanish within minutes. Additionally, if you have multiple devices at your disposal, you might use them concurrently to improve your chances of successfully completing the purchase.

- Verify Authenticity: With the allure of exclusivity comes the risk of encountering counterfeit or misrepresented items, making authenticity verification a non-negotiable part of the purchasing process. It is important to demand clear proof of authenticity from the seller, such as official certificates, holograms, or serial numbers that correlate with records issued by the label or artist. Detailed images of the pressing, along with documentation that verifies its origin, should be readily available before you commit to a purchase. Familiarize yourself with the subtle markers of genuine pressings by researching the characteristics distinguishing authentic items from replicas.

With thoughtful preparation and an active approach, your journey into the world of rare vinyl becomes both a rewarding passion and a testament to your commitment to quality and authenticity.

The world of vinyl is expansive, with countless avenues for exploration and appreciation. As we continue to witness a resurgence in vinyl popularity, the importance of preserving this craft becomes even more evident. Both seasoned and new collectors play a crucial role in sustaining the vinyl industry, encouraging ongoing innovations, and ensuring that the art of vinyl pressing continues to thrive.

![$Uicideboy$ - Thy Kingdom Come [Clear]](http://vinyl.com/cdn/shop/files/4435583-3407920.jpg?v=1754460746&width=5760)

![(hed) p.e. - New And Improved [Pink]](http://vinyl.com/cdn/shop/files/4425252-3389420.jpg?v=1746578880&width=5760)

![The Grateful Dead - The Music Never Stopped [6LP Box Set]](http://vinyl.com/cdn/shop/files/The_Grateful_Dead-The_Music_Never_Stopped__6LP_Box_Set.jpg?v=1747729623&width=5760)

![Fleetwood Mac - Fleetwood Mac 1975 To 1987 [Clear 6LP Box Set]](http://vinyl.com/cdn/shop/files/2RHILP81833__61378.jpg?v=1743391443&width=5760)

![Taylor Swift - 1989 (Taylor's Version) [2LP Crystal Skies Blue]](http://vinyl.com/cdn/shop/files/taylor_swift_1989_taylors_version.jpg?v=1734389117&width=5760)

![Grace Jones - Nightclubbing [Gold]](http://vinyl.com/cdn/shop/files/4407705-3329230.jpg?v=1742429522&width=5760)

![Debbie Harry - KooKoo [2LP Clear]](http://vinyl.com/cdn/shop/files/4025259-2960387.jpg?v=1682465873&width=5760)

![Miles Davis - Kind of Blue [180-gram]](http://vinyl.com/cdn/shop/files/Y4LPMD03.webp?v=1742198237&width=5760)

![Various Artists - Once Upon A Time: The Tarantino Sound [Red 180-Gram]](http://vinyl.com/cdn/shop/files/4376720-3283530.jpg?v=1733870948&width=5760)